One For All

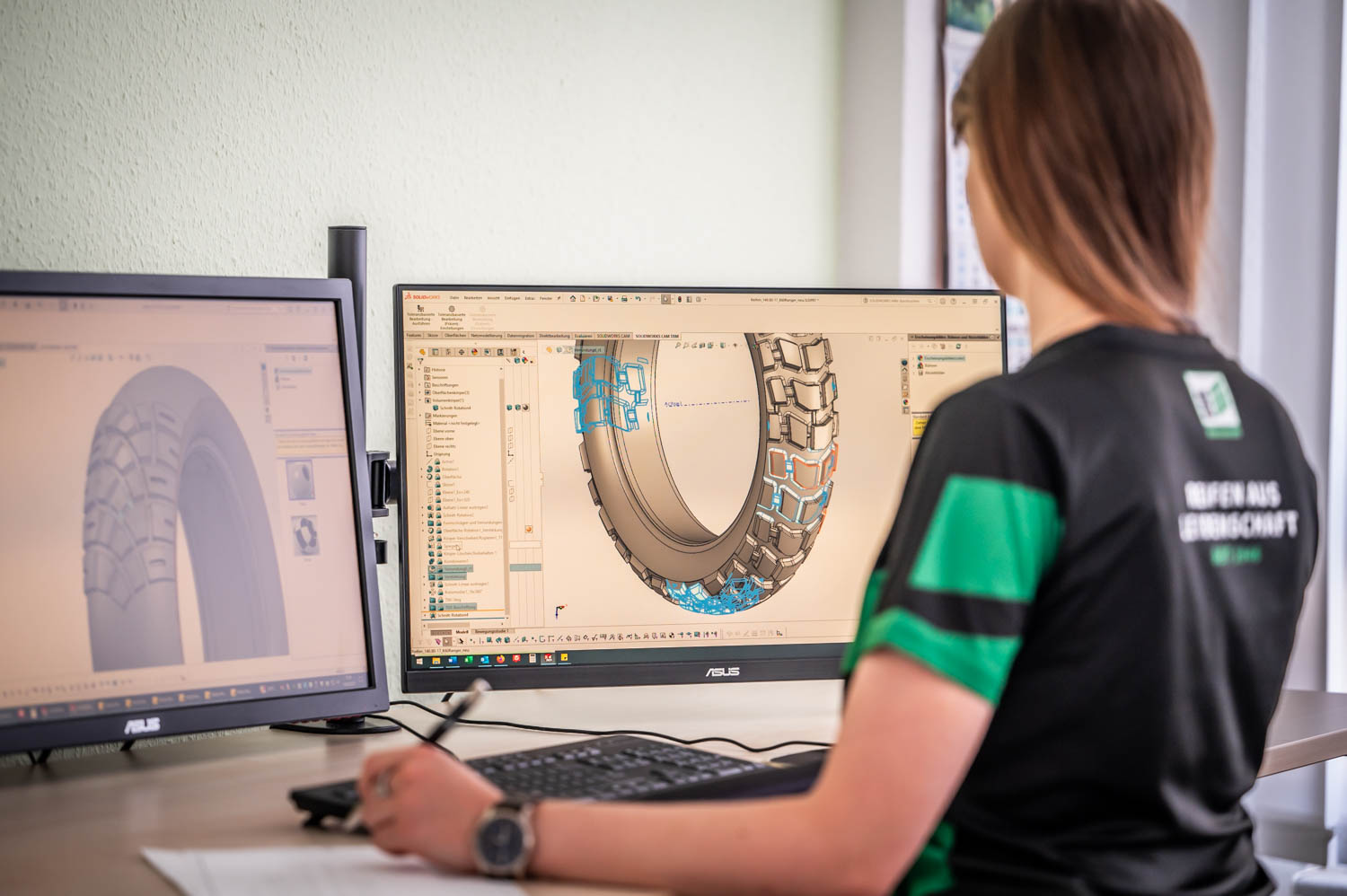

The fact that our products excellently combine functional properties and appealing design is both the goal and the incentive to produce tires with all of our passion. Therefore, we make no compromises in terms of their design and do all the whole construction by ourselves. In this regard, our expertise starts with our own materials research. Thanks to our extensive know-how in this area, we are able to develop our own tire compounds and create innovative, tailor-made products that precisely meet the demands of our customers. Our products deliver what they promise, because we attach major significance to a thorough quality assurance. Comprehensive tire tests, test drives by dedicated employees and our own test rigs guarantee a secure and reliable driving experience.

Well conceived and well made - while working on the design of our tires in the development department, we bring each model to life in the production department by flexible manufacturing processes. Over 120 work steps with a high level of craftsmanship ensure the highest possible quality.

The production begins with the processing of our self-developed material mixtures, the cord fabric and the bead wire cores, which form the fundamental elements of our tires. These raw materials are then carefully processed and assembled by our employees on the conversion machines. Afterwards, the blank gets shaped into the desired form by applying high pressure and heat during the vulcanization process and the final tire occurs. Before the tires leave our plant, they are subjected to an intensive, manual final inspection and marked appropriately.

Further Trades

To ensure that our production processes run smoothly, a large number of additional trades are required. We can implement technical adjustments on site at any time in our own metalworking store, factory workshop and electrical workshop.

Our national sales structure mainly concentrates on B2B retailers, specialist dealers and two-wheeler repair shops, while our export department supplies more than 60 countries around the world. To find a dealer near you, click here.