FAQ

-

Tires that are flawlessly produced and properly stored are high-quality assets that can be sold and installed without concern up to an age of 5 years. Tires are homogeneous products, and their components, when stored correctly, undergo minimal aging. Heidenau Tires adheres to the approach agreed upon by the Federal Association of Tire Trade and Vulcanizer Craft e.V. and leading tire manufacturers:

- Tires with a storage time of up to 3 years can be sold as factory new.

- Tires with a storage time of up to 5 years can be sold as new.

- Shorter deadlines are advisable if a specific tire product has undergone significant technical changes or significant model care measures since production.

- Tires older than 10 years should only be used if they have been continuously in use under normal conditions. They should not be reshuffled and only used in normal operation.

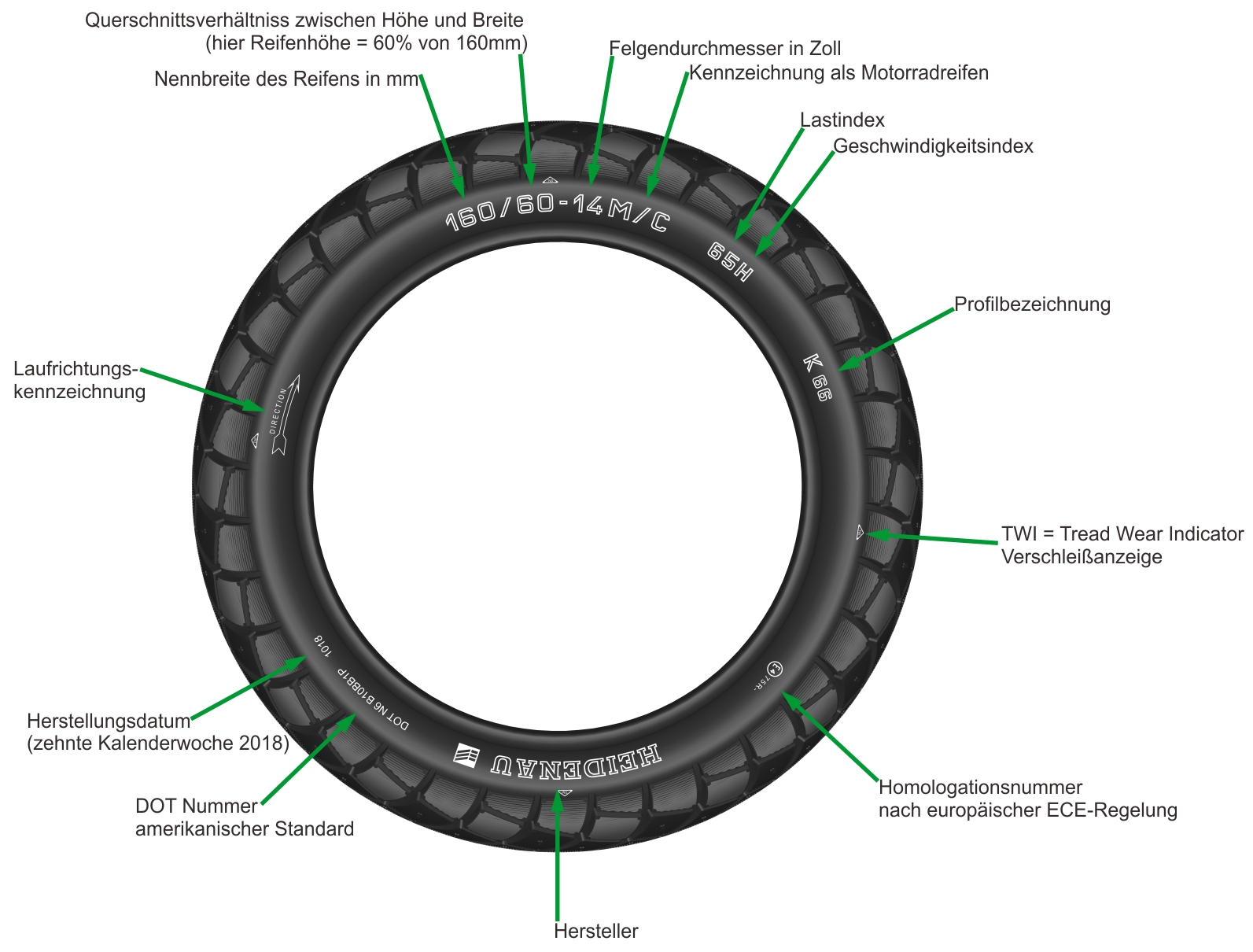

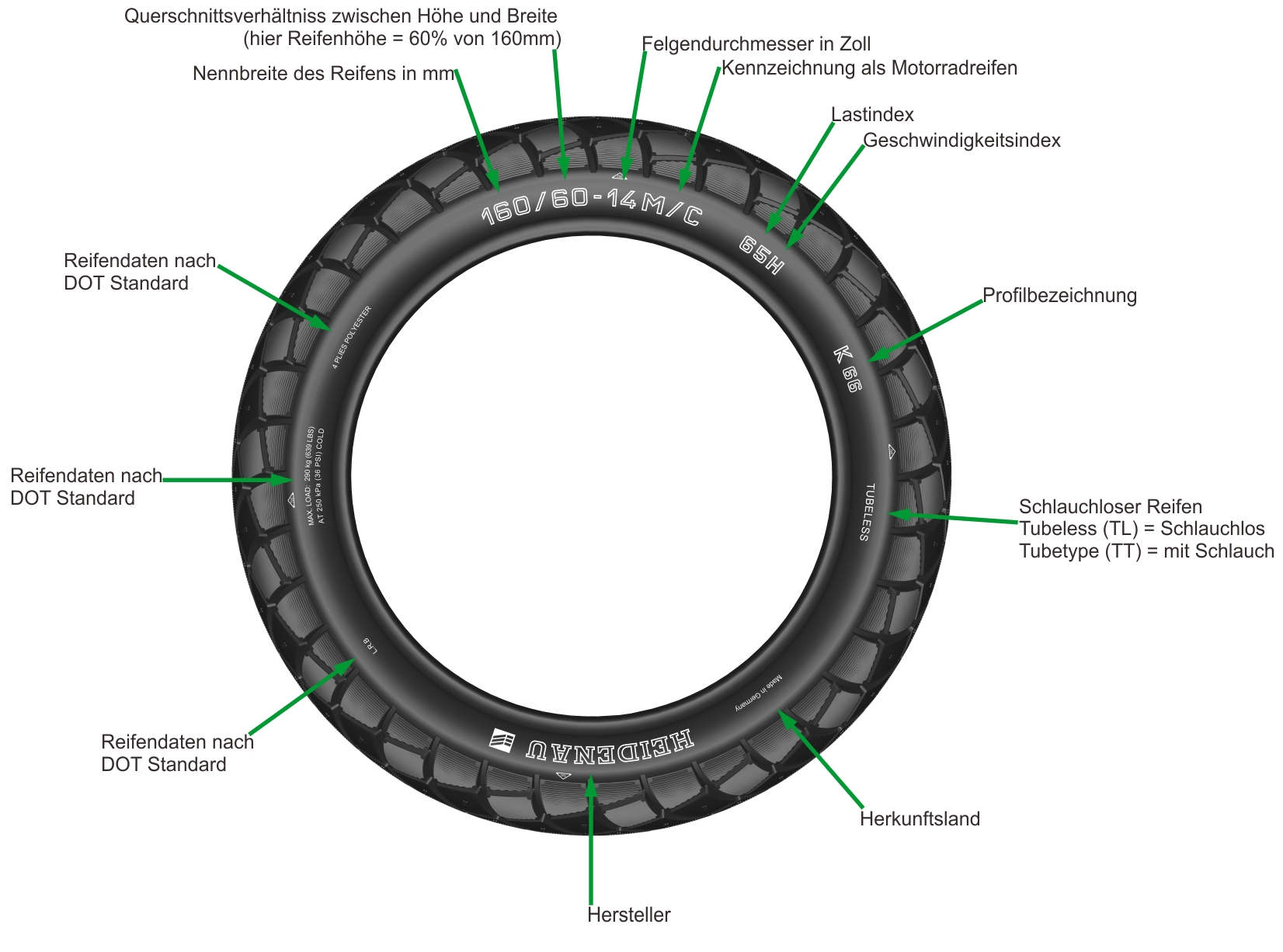

How to identify the production date of Heidenau motorcycle tires: Find the production date of each tire on the sidewall after the "DOT" inscription (Note: the date stamp is only on one side of the tire!).

For tires manufactured after 1999, the last four digits indicate the production date. For example, a tire with a DOT number ending in 4503 was produced in the 45th week of 2003.

-

-

Manufacturer's certificate for tire conversion:

Heidenau Tire Factory confirms with the manufacturer's certificate that installation instructions and restrictions on tire size, according to Chapter 1, Annex III, Directive 97/24/EC and its successors 168/2013/EU in conjunction with 3/2014/EU Annex XV, are adhered to.

The listed tire options in the manufacturer's certificate deviate from the original tires provided by the vehicle manufacturer in the registration certificate Part I, the data confirmation, the Certificate of Conformity (CoC), or the vehicle approval in terms of construction type and/or size designation or fall below the load or speed index. When mounting the tires, a modification occurs, leading to the revocation of the operating license according to § 19 (2) StVZO. If the vehicle is otherwise in an approved condition, an assessment according to § 21 due to § 19 (2) StVZO is possible and immediately necessary after modification. The operating license must then be reissued.

Heidenau Tire Factory confirms that:

- The load and speed index of the tire covers the respective axle load of the motorcycle at maximum speed. Exceptions apply to M+S tires according to §36 StVZO.

- The clearance check on standard vehicles has been carried out in advance. No hindrance to the movement of the wheel/wheels could be determined.

- The dynamic expansion with a changed tire design does not lead to a hindrance to the movement of the wheel/wheels.

- The tires can be mounted without restrictions on the standard rims.

- The handling has been tested through dynamic tests up to the maximum speed with the modified tires. No negative changes were observed.

The use of the tire combinations listed in the manufacturer's certificate assumes that the vehicle is in an unchanged original state.

Tire recommendation for motorcycles:

The tire options listed in the tire recommendation have component approval according to ECE Regulation 75 and correspond to the information in the registration certificate Part I, data confirmation, Certificate of Conformity (CoC), or vehicle approval.

Therefore, there is no change or revocation of the operating license according to § 19 (2) StVZO when mounting these tire combinations.

The use of the listed tire combinations requires that the vehicle described in the tire recommendation is in an unchanged original condition according to the granted EU type approval/operating license.

While carrying this information is not mandatory (§19 Abs.4 StVZO), it is recommended to avoid unnecessary difficulties.

Further information on assessing wheel/tire combinations on motorcycles can be found at:

-

-

-

-

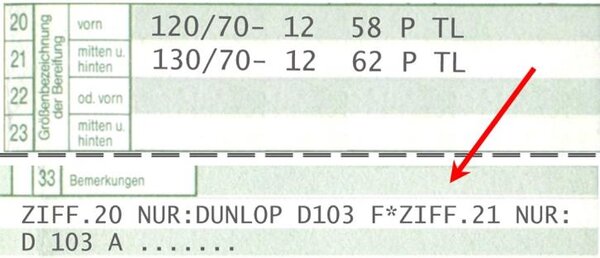

Manufacturer binding exists when the vehicle registration certificate (Lines 20-23 or Remarks Line 33) includes a specific tire manufacturer or profile alongside tire size, load, and speed index.

Some motorcycle manufacturers abstain from requiring specific tire brands but obligatorily recommend only the tire models with which the motorcycle was originally homologated, as noted in the owner's manual. Disregarding these recommendations places the responsibility on the vehicle owner. In practice, this means that a motorcyclist must seek tire approvals from other manufacturers if they choose not to use homologated tires or if those tire models are no longer available.

-

-

-

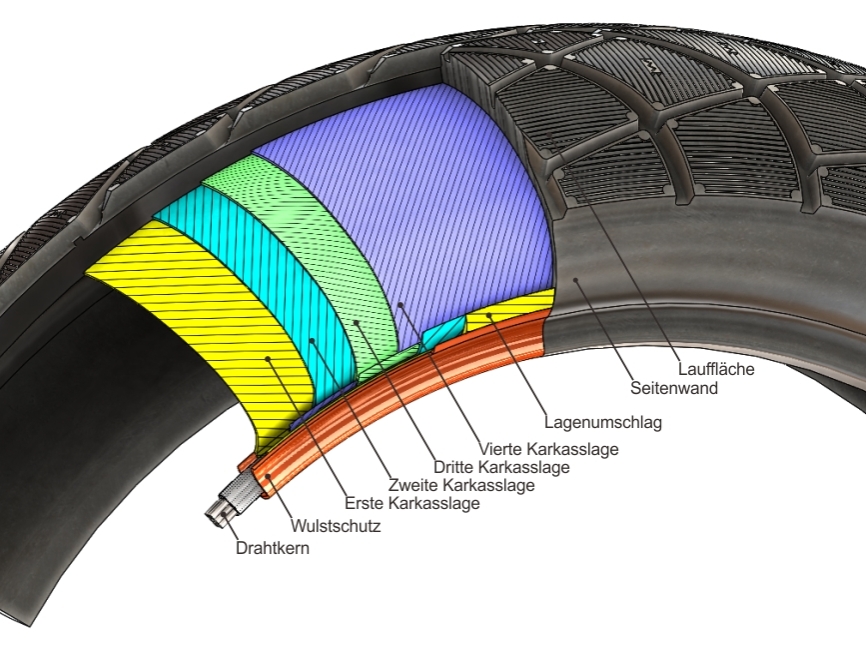

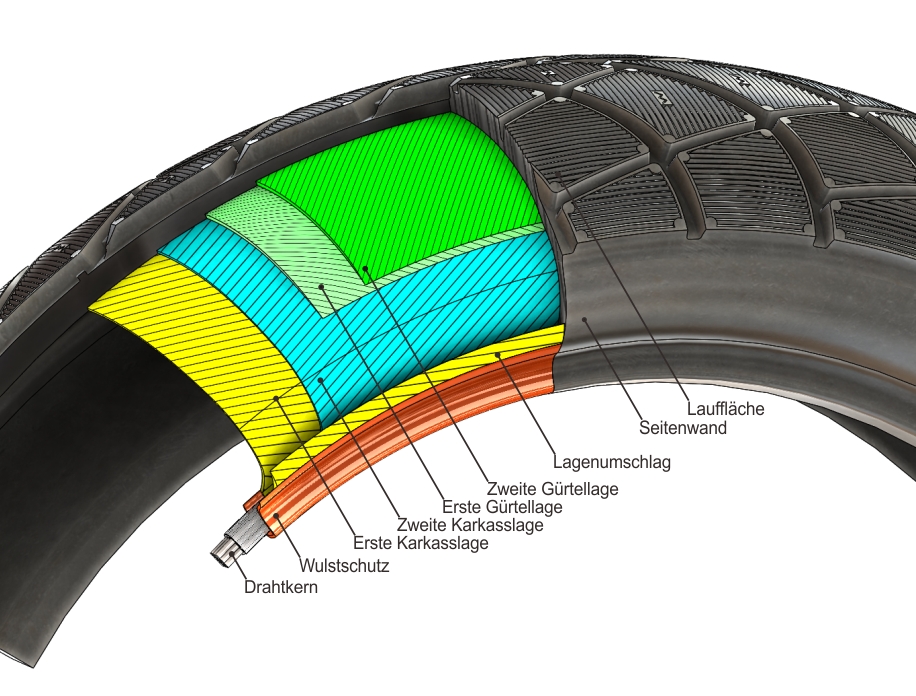

The carcass gives the tire its shape and strength. In the case of a diagonal tire, it consists of several layers of cords arranged crosswise, with the direction of the threads changing in each layer. They are oriented diagonally to the direction of travel (approximately 30 - 40°).

-

-

-

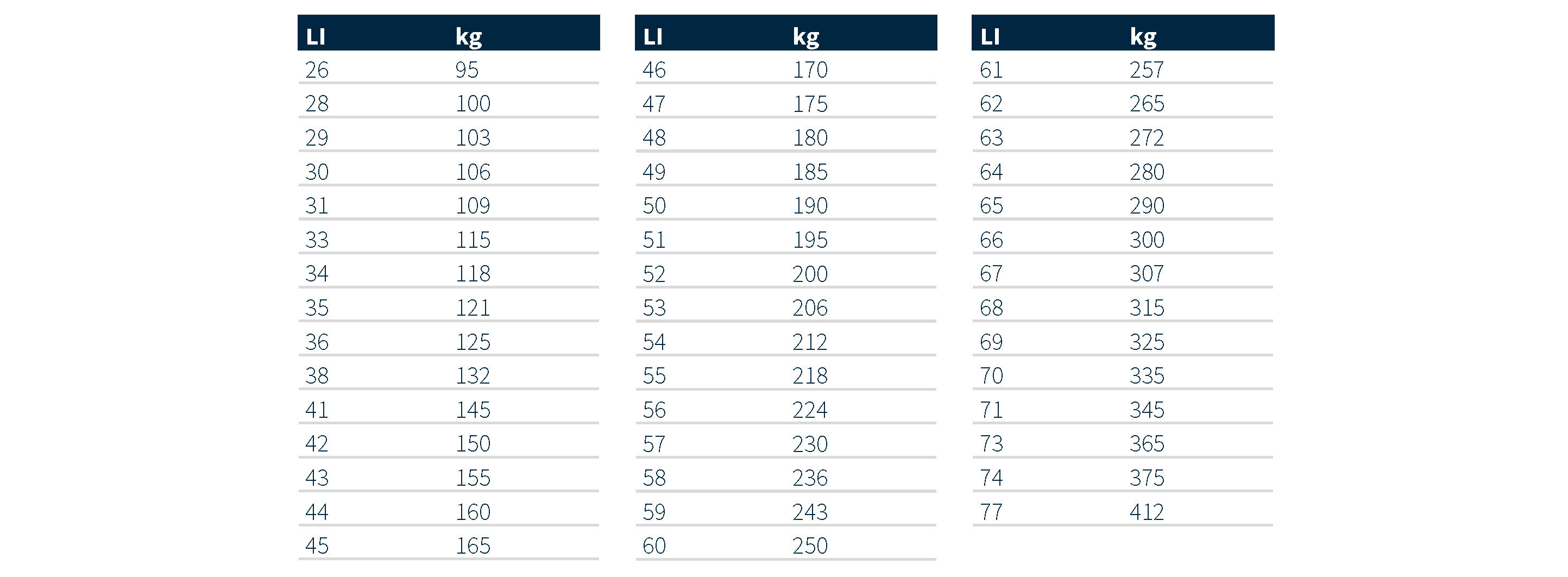

The Load Index indicates the permissible load capacity of a motorcycle tire through a numerical code. A table can be used to determine the maximum load capacity of the tire in kilograms based on the Load Index. It is also referred to as the Load Capacity Code.

-

-

-

Motorcycle tires play a significant role in safety, and their air pressure should be regularly and properly checked. In addition to tread depth (see TWI), particular attention should be paid to air pressure. Insufficient air pressure can lead to severe consequences, causing excessive deformation of the sidewalls, material fatigue, and, in extreme cases, tire failure.

Both too low and too high air pressure pose risks to road safety. Regularly check and adjust the tire pressure as specified by the manufacturer in the manual or directly on the motorcycle (e.g., swingarm, seat, etc.). Proper checks are possible only before riding, as tire heating during operation leads to increased pressure, which should not be reduced.

Maintaining the correct air pressure enhances tire durability, saves fuel, and improves motorcycle safety.

Recommendations:

- Check air pressure at least once a week.

- Increase rear wheel air pressure by 0.2 bar when riding with a passenger.

- After checking, screw the valve cap back on.

-

-

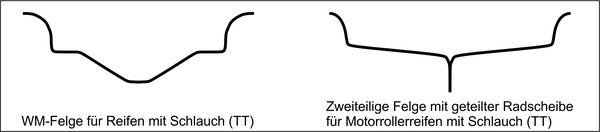

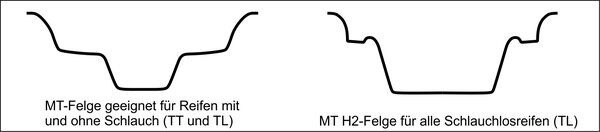

The new tire and the rim must correspond in diameter and be approved as a combination for the respective vehicle type. Only dimensionally sound, clean, and rust-free rims should be used, which must not be damaged, deformed, or worn.

Tire mounting should be carried out by a professional. Both tire beads and rim must be fully coated on both sides with mounting paste or soapy water. Please avoid using oil- or silicone-based fluids. Pay attention to the tire's directional arrow. Do not use tire sealants.

WARNING! Improper tire mounting can lead to tire rupture. The energy released can cause life-threatening injuries. Therefore, tires should be mounted by a professional.

-

-

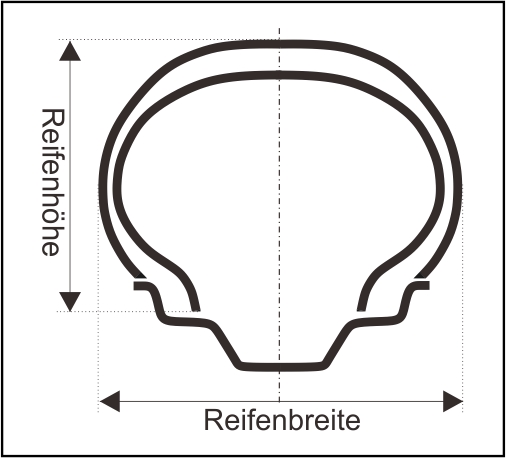

Low-profile tires have a height-to-width ratio of less than 1. This means that such a tire, when viewed in cross-section, has a lower height than its width. The lower height provides better straight-line and cornering performance, as well as increased force transmission during braking and acceleration.

-

The tire industry has long recognized the role of the consumer in regular tire maintenance. The decision of when to replace a tire rests with its owner. The tire owner should consider factors such as usage conditions, maintenance intervals, storage conditions, visual inspection, and the tire's dynamic behavior. If there are questions regarding the tire's lifespan, consumers are encouraged to consult a tire specialist. The following information and recommendations have been compiled to assist in determining the maximum possible lifespan of a tire.

Tires are designed and manufactured to provide high mileage and maximum utility depending on their purpose. Proper maintenance is necessary to prevent tire damage and misuse that could render a tire unusable.

Consumers play a crucial role in tire care and maintenance.

Tires should be taken out of service for various reasons, such as reaching the minimum tread depth and after damage or misuse (puncture or cut injuries, impact breaks, cracks, bulging, underinflation, overloading, etc.). Therefore, tires should undergo routine inspections at least once a month. These routine inspections become even more crucial the longer the tires have been in use. If tire damage is found or even suspected, a tire specialist should be consulted to determine whether the tire can continue to be used. These routine inspections must be conducted even if the vehicle is equipped with a Tire Pressure Monitoring System (TPMS).

Consumers are strongly urged to not only visually inspect their tires but also observe any changes in dynamic behavior, such as increased air loss, noises, or vibrations. These could be indications that the tire is no longer in proper condition and should be promptly removed from service to avoid tire failure. Similarly, if a motorcyclist detects a severe impact or blow against the tire during operation, it is essential to ensure that the tire is promptly inspected afterward.

Tire storage, accommodation, and tire changes are also crucial factors for the potential lifespan of a tire.

Recommended Tire Lifespan

Heidenau has no technical documents or information specifying a particular age at which a tire should be taken out of service. Nevertheless, we recommend, in conjunction with other tire and vehicle manufacturers, that all tires older than ten (10) years be replaced with newer ones. This recommendation applies even to tires that still appear to be usable externally and whose tread depth has not reached the legally prescribed minimum. If vehicle manufacturers, based on their knowledge of the specific application, recommend a different chronological age after which a tire should be replaced, we endorse such recommendations in any case. Consumers should be aware that most tires may need replacement before the recommended service life due to wear or other reasons. A lifespan recommendation does not absolve the consumer of the responsibility to replace tires when necessary.

Determining the Production Date of Tires According to Date Coding

The production date of each tire is indicated on the sidewall after the "DOT" symbol. For tires manufactured after the year 1999, the last four digits represent the production date. The first two digits indicate the production week (ranging from "01" to "53"). The last two digits represent the production year (Example: A tire labeled "DOT XXXXXX3517" was produced in the 35th calendar week of 2017).

The potential lifespan of a tire depends on the cumulative effects of storage, operational, and service demands it encounters throughout its life (loading, speed, inflation pressure, punctures, etc.). Since these conditions can vary significantly, predicting the potential lifespan of each tire based solely on its chronological age is not feasible.

-

Worn-out tires significantly affect vehicle performance and should be replaced promptly. Particularly, the front tire, crucial for stability, should be replaced when the tread depth is only 2 mm. It is also recommended to renew the rear tire at a tread depth of 2 mm.

German regulations require a minimum tread depth of 1.6 mm for motorcycles over 125 cc. Exceptions are small and light motorcycles, for which a minimum of 1.0 mm is required.

-

-

-

The sidewall transfers circumferential and lateral forces, significantly contributing to damping and suspension characteristics. Additionally, technical data information is provided on the sidewall (see tire markings).

-

Key safety recommendations for motorcycle tires include adhering to the prescribed minimum air pressure, regular pressure checks, not exceeding the maximum load capacity, avoiding impact stresses (e.g., curbs), regularly inspecting tires for damage, maintaining a tread depth of at least 2 mm, using prescribed tires for optimal performance, selecting an appropriate tube (if necessary), protecting the valve with a cap, using new valves for tubeless tires, using only prescribed and undamaged rims, and having tire mounting performed by a professional.

-

Heidenau has developed motorcycle winter tires based on extensive experience in producing two-wheeler winter tires. These tires use Enduro profiles with a higher negative share, combined with a specially developed silica compound for motorcycle winter use. This combination provides high grip and self-cleaning in icy temperatures, enhancing safety compared to standard versions. Silica versions offer significant advantages in wet and dry grip and improved braking performance at low temperatures. Winter tires with the silica compound are marked SiO2 on the tire sidewall.

-

The uniqueness of Snowtex® tires lies in their two-part tread design.

It comprises a baseplate with a regular compound and a duplex plate with fiber-reinforced protector rubber. The high-quality silica rubber compound contained in it is designed for low temperatures, exhibiting excellent cold elasticity essential for traction on wet and snow-covered roads. The incorporated fabric fibers also create a rough surface structure, enhancing grip on slippery roads.

-

-

-

The raised section on the tread in a groove indicates tread wear. When the tread is worn down to the indicator, the legal minimum tread depth is reached. Heidenau's indicators comply with Germany's legally required 1.6 mm minimum tread depth.

Note that mopeds, light mopeds, small motorcycles, and light motorcycles have different minimum tread depth requirements (see Tread Depth).

-

In this table, you will find the conversion of inch motorcycle tire sizes to the metric measurement and vice versa.

Please note that any deviation from the original tire size will alter the rolling circumference, and tire clearance must be checked. Also, pay attention to the specified load index of the tires and adjust the tire pressure if necessary. Follow the recommendations of the vehicle manufacturer. If there is no approval from the vehicle or tire manufacturer, a modification approval must be obtained from an inspection organization.

Legal Disclaimers

All rights reserved. |